The dawn of the 21st century has seen a profound transformation in the field of material science, driven by the discovery and development of nanomaterials—substances structured on the scale of nanometers, where quantum and surface effects dominate their behavior. Among these, carbon nanotubes (CNTs) and graphene have emerged as the most revolutionary, reshaping the boundaries of physics, chemistry, and engineering. Both materials are forms of carbon, yet their structures and properties are so extraordinary that they have redefined what scientists believed possible in terms of strength, conductivity, and flexibility.

Carbon nanotubes are cylindrical structures composed of rolled graphene sheets, exhibiting exceptional tensile strength, electrical conductivity, and thermal stability. Graphene, on the other hand, is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice—an atomic sheet that is both remarkably strong and incredibly light. These materials represent not only new building blocks for future technologies but also a paradigm shift in our understanding of matter at the atomic level.

From electronics to medicine, from aerospace to energy storage, the applications of carbon nanotubes and graphene continue to expand. Their unique mechanical, electrical, and chemical characteristics promise to transform multiple industries and even inspire new scientific fields. This essay explores how these nanostructures are revolutionizing material science, focusing on their discovery, synthesis, fundamental properties, and real-world applications.

Structure, Properties, and Theoretical Foundations

Both carbon nanotubes and graphene owe their remarkable behavior to carbon’s versatile bonding nature. Carbon atoms can form sp² hybridized bonds that create strong, planar structures—foundational for graphite, CNTs, and graphene alike. However, the geometric arrangement of these bonds defines the differences among these forms.

Graphene consists of a single layer of carbon atoms bonded in a two-dimensional hexagonal lattice. It can be visualized as a single sheet extracted from graphite. What makes graphene exceptional is its combination of mechanical and electronic perfection: it is the thinnest material known, yet also one of the strongest, with a tensile strength around 130 GPa and a Young’s modulus exceeding 1 TPa. Its electrons behave as massless Dirac fermions, leading to extraordinarily high electrical mobility—up to 200,000 cm²/V·s under ideal conditions. This allows graphene to conduct electricity more efficiently than copper, while being almost transparent and flexible.

Carbon nanotubes, discovered in 1991 by Sumio Iijima, can be thought of as rolled-up graphene sheets forming cylindrical structures. Depending on the rolling direction (chirality) and diameter, CNTs can exhibit metallic or semiconducting behavior. There are two main types: single-walled carbon nanotubes (SWCNTs), consisting of one cylindrical graphene layer, and multi-walled carbon nanotubes (MWCNTs), composed of multiple concentric layers. CNTs possess exceptional mechanical strength, with tensile strengths up to 63 GPa and stiffness values that rival diamond. Their aspect ratio (length-to-diameter ratio) can exceed 1000, allowing them to act as near-perfect one-dimensional conductors.

A comparison of their key properties is summarized below:

| Property | Graphene | Single-Walled CNT | Multi-Walled CNT |

|---|---|---|---|

| Structure | 2D single layer of carbon atoms | 1D cylinder of rolled graphene | Multiple concentric cylinders |

| Electrical Conductivity | ~10⁶ S/m | Metallic or semiconducting depending on chirality | Metallic (outer shells dominate) |

| Tensile Strength | ~130 GPa | ~63 GPa | ~25 GPa |

| Elastic Modulus | ~1 TPa | ~1 TPa | ~0.8 TPa |

| Thermal Conductivity | Up to 5000 W/m·K | Up to 3500 W/m·K | ~3000 W/m·K |

| Transparency | ~97.7% | Opaque | Opaque |

The table highlights that while graphene excels as a two-dimensional conductor and structural material, carbon nanotubes offer greater versatility due to their variable chirality and tubular form, enabling both metallic and semiconducting properties in the same material family.

At the quantum level, both materials exhibit phenomena that challenge classical physics. In graphene, electrons move as if they have no mass, leading to the “relativistic” behavior of charge carriers even at room temperature. This property contributes to ballistic transport over submicron distances, meaning electrons can travel without scattering—an ideal feature for high-speed electronics. Similarly, CNTs display quantized conductance, where current flows through discrete channels, offering opportunities for nanoscale transistors and quantum devices.

Synthesis and Processing Techniques

The development of CNTs and graphene has required the refinement of synthesis techniques capable of controlling atomic precision and scalability. Since both materials are pure carbon, the challenge lies not in composition but in structure—achieving uniformity in diameter, chirality, and layer number is crucial for consistent performance.

Graphene Synthesis

Graphene can be produced through several methods, each with distinct trade-offs between quality and scalability.

- Mechanical Exfoliation, famously used by Andre Geim and Konstantin Novoselov in their 2004 Nobel-winning experiment, involves peeling layers from graphite using adhesive tape. It produces high-quality, defect-free graphene ideal for research, but is impractical for mass production.

- Chemical Vapor Deposition (CVD) has become the dominant industrial method. In CVD, carbon-containing gases (like methane) are decomposed on metal substrates such as copper or nickel at high temperatures, forming graphene films. These films can later be transferred to other surfaces.

- Chemical or Electrochemical Reduction of Graphene Oxide provides a scalable route to produce functionalized graphene with controlled oxygen content, making it suitable for composites and coatings.

Carbon Nanotube Synthesis

CNTs are typically produced through three main methods:

- Arc Discharge, where carbon vapor is created between graphite electrodes under an inert atmosphere.

- Laser Ablation, which uses high-power laser pulses to vaporize carbon targets containing catalysts.

- Chemical Vapor Deposition, similar to graphene synthesis, allows controlled growth of CNTs on catalytic nanoparticles, enabling industrial-scale production.

CVD remains the most versatile approach, as it allows tuning of CNT diameter, length, and alignment through temperature, catalyst, and gas flow adjustments. Vertically aligned CNT forests can be grown, forming films and arrays useful for sensors, electrodes, and reinforcement materials.

Processing these nanomaterials into usable macroscopic forms—films, composites, fibers—remains a central challenge. Dispersion and alignment are critical: CNTs tend to agglomerate due to van der Waals forces, while graphene sheets can restack into graphite-like layers. Functionalization through chemical modification, such as attaching carboxyl or amine groups, helps improve dispersion in solvents and polymer matrices without compromising conductivity or strength.

Applications in Modern Science and Industry

The remarkable combination of strength, conductivity, and chemical stability makes CNTs and graphene indispensable across numerous sectors. These applications reflect not only incremental improvements to existing materials but entirely new functionalities impossible before the nanocarbon revolution.

Electronics and Optoelectronics

Both graphene and CNTs exhibit exceptional electron mobility and tunable band structures, making them ideal candidates for next-generation electronics. Graphene’s high carrier mobility enables faster and thinner transistors compared to traditional silicon-based devices. Transparent and flexible graphene electrodes are now being integrated into touchscreens, OLED displays, and photovoltaic cells.

CNTs, due to their one-dimensional nature, can act as either metallic conductors or semiconductors depending on chirality. This property allows the fabrication of nanoscale transistors, diodes, and interconnects. Networks of semiconducting CNTs are being developed as active channels in flexible electronics, while metallic CNTs serve as lightweight alternatives to copper wiring in aerospace applications.

Energy Storage and Conversion

Graphene and CNTs also play a transformative role in energy technologies. Their large surface area, high conductivity, and mechanical resilience make them excellent candidates for electrodes in batteries and supercapacitors. In lithium-ion batteries, graphene-enhanced anodes enable faster charge and discharge cycles by facilitating ion diffusion. CNTs act as conductive scaffolds that maintain structural integrity during repeated cycling, improving battery lifespan.

In fuel cells, CNT-based catalysts enhance reaction efficiency and reduce the reliance on expensive noble metals. Graphene membranes with atomic-scale pores show potential for hydrogen separation and desalination, further extending their role in clean energy systems.

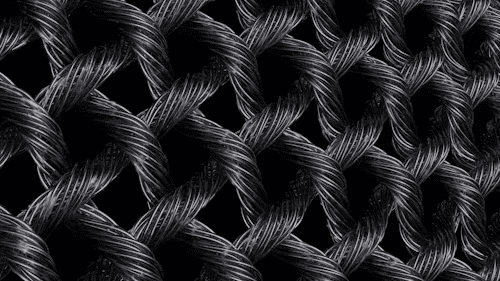

Composites and Structural Materials

Perhaps the most visible impact of these nanocarbons lies in composites. Adding a small fraction of CNTs or graphene to polymers, metals, or ceramics dramatically enhances mechanical and thermal properties. Aerospace manufacturers use CNT-reinforced composites for lightweight, high-strength components, reducing fuel consumption while improving performance. Graphene-polymer blends have found applications in sports equipment, automotive parts, and protective coatings.

Biomedical and Environmental Uses

The biocompatibility and functional versatility of carbon nanomaterials open promising avenues in medicine. CNTs can serve as drug delivery vectors, capable of transporting molecules directly into cells. Graphene oxide, with its high surface area and ease of functionalization, is being investigated for biosensors, tissue engineering scaffolds, and antibacterial coatings.

Environmental applications include CNT-based filters that remove heavy metals or organic pollutants from water and air, as well as graphene-based membranes for gas separation and desalination. These innovations demonstrate the capacity of nanomaterials to contribute not just to technological progress but to global sustainability.

Challenges, Ethical Considerations, and Future Perspectives

Despite their extraordinary promise, carbon nanotubes and graphene face several obstacles before achieving their full industrial and societal impact. Chief among these are issues of scalability, cost, safety, and environmental responsibility.

Scalability and Uniformity.

Producing large quantities of CNTs or graphene with consistent properties remains technically demanding. Variations in chirality or defects can dramatically alter electrical behavior, making it difficult to standardize materials for commercial electronics. Developing reliable characterization and sorting techniques is essential for industrial integration.

Toxicity and Environmental Impact.

While carbon itself is biologically benign, the nanoscale form introduces new concerns. CNTs, for instance, can resemble asbestos fibers in shape and persistence, raising questions about respiratory exposure and long-term biocompatibility. Graphene oxide may cause oxidative stress in some biological systems. Rigorous toxicological studies and safe handling guidelines are vital to ensure that the benefits of nanotechnology do not come at the expense of human health or ecosystems.

Economic and Ethical Dimensions.

The proliferation of nanotechnology raises ethical questions about accessibility, labor conditions, and potential misuse. As advanced materials become central to emerging industries—such as AI hardware, defense, and medical implants—inequalities in access to these technologies could widen. Responsible innovation frameworks emphasizing transparency and sustainability must accompany technical progress.

Future Outlook

Looking ahead, the future of CNTs and graphene is one of integration rather than isolation. Researchers envision hybrid systems combining these nanomaterials with other emerging technologies—such as perovskites for solar cells, MXenes for energy storage, or biopolymers for green composites. Three-dimensional architectures based on graphene foams and CNT networks may lead to “smart materials” capable of self-healing, sensing, and energy harvesting simultaneously.

Advancements in quantum computing and neuromorphic engineering are particularly promising frontiers. Graphene’s tunable bandgap and ballistic transport could enable ultra-fast quantum transistors, while CNT networks mimic neural connectivity for brain-inspired computing. In parallel, advances in additive manufacturing are enabling the 3D printing of graphene-based components, merging precision design with nanoscale functionality.

Ultimately, the significance of CNTs and graphene extends beyond their individual properties. They represent a fundamental reimagining of matter—proof that by manipulating structure at the atomic scale, humanity can engineer materials with unprecedented capabilities. This realization is reshaping education, industry, and philosophy alike, heralding a future in which the boundaries between chemistry, physics, and biology dissolve into the shared language of nanoscience.

Conclusion

Carbon nanotubes and graphene stand as twin pillars of the nanotechnology revolution, redefining what materials can achieve. Their strength exceeds that of steel, their conductivity surpasses that of copper, and their flexibility rivals that of polymers. Together, they symbolize the power of atomic precision—a capacity to design matter not by bulk composition, but by geometry and quantum behavior.

Yet the revolution they promise is still unfolding. Challenges of mass production, cost, and environmental stewardship must be overcome through collaborative innovation across disciplines. As researchers refine synthesis methods and governments implement sustainable policies, CNTs and graphene will transition from laboratory marvels to integral components of everyday life.

In their atom-thin lattices lies a glimpse of the next industrial age: one defined not by the extraction of resources but by the intelligent design of matter itself. Carbon, the element of life, has once again proven to be the element of the future—binding the organic and technological worlds through the elegance of its simplest forms.