From the gleam of a gold-plated watch to the resilience of aerospace components, the surfaces of materials define both their function and appeal. Electroplating, though often unnoticed by the casual observer, is a silent architect of durability, efficiency, and beauty in modern life. Beneath its seemingly simple layers lies a sophisticated dance of ions, electrons, and chemical interactions—a dance governed by the principles of surface chemistry.

This exploration delves into the science behind electroplating, revealing how meticulous control over material surfaces transforms ordinary objects into technologically advanced, long-lasting, and aesthetically refined creations. By understanding these invisible interfaces, we gain insight into a process that bridges chemistry, engineering, and innovation, shaping not just metals, but the very progress of modern industry.

Introduction to Electroplating and Surface Chemistry

Electroplating is a cornerstone of modern materials science and industrial chemistry. It is a process that involves depositing a thin layer of metal onto the surface of a substrate, typically to improve its physical, chemical, or aesthetic properties. This seemingly simple technique is underpinned by complex electrochemical principles and a deep understanding of surface chemistry. The interaction between the deposited layer and the underlying material is critical, influencing adhesion, corrosion resistance, conductivity, and wear properties.

Surface chemistry, the study of chemical reactions and physical phenomena occurring at interfaces, is central to electroplating. The surface of a material is distinct from its bulk, often exhibiting unique properties such as increased reactivity, altered energy states, and specialized electronic behavior. By manipulating these surface characteristics through electroplating, scientists and engineers can enhance material performance for a wide array of applications, ranging from industrial machinery to consumer electronics.

The interplay between electroplating and surface chemistry has led to transformative advancements in materials science. Protective coatings prevent corrosion, decorative coatings improve aesthetics, and functional coatings enhance electronic and catalytic properties. The precision and versatility of electroplating make it a foundational tool in manufacturing, nanotechnology, and environmental engineering.

The Electroplating Process and Underlying Principles

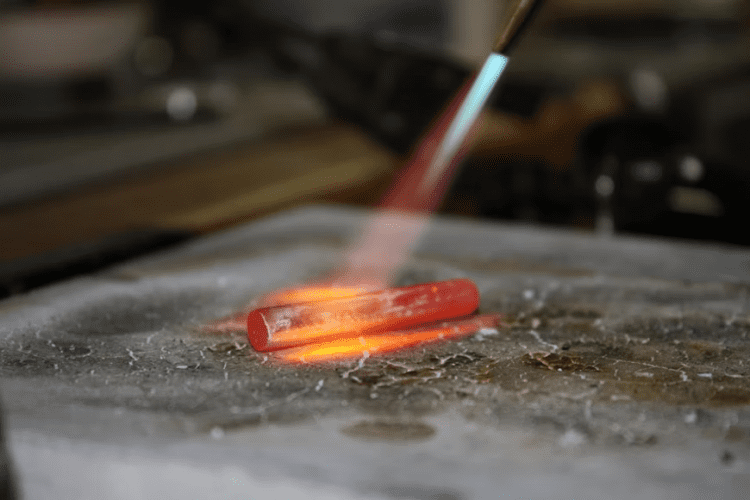

Electroplating relies on the principles of electrochemistry, particularly the movement of ions in solution and their reduction at the cathode. A typical electroplating setup consists of an electrolyte solution containing metal ions, a cathode (the object to be plated), and an anode (often made of the plating metal). When a direct current is applied, positively charged metal ions migrate toward the cathode, where they gain electrons and form a solid metallic layer.

The quality of the electroplated layer depends on multiple factors:

- Current density: Too high a current can lead to rough, porous deposits, while too low a current may produce uneven plating.

- Electrolyte composition: Additives, pH, and metal ion concentration influence deposition rate, morphology, and adherence.

- Temperature and agitation: These parameters affect ion mobility, nucleation rate, and uniformity of the coating.

Surface chemistry plays a critical role in this process. The substrate surface must often be cleaned and activated to remove oxides, oils, and contaminants that could inhibit adhesion. Techniques such as acid etching, ultrasonic cleaning, and plasma treatment are commonly employed to prepare the surface. The interaction between the substrate and the deposited metal determines coating integrity, mechanical performance, and resistance to environmental degradation.

Electroplating is not only about coating with a single metal; it also includes multilayer and alloy plating, where layers of different metals or metal alloys are sequentially applied. This allows engineers to combine desirable properties, such as hardness, conductivity, and corrosion resistance, in a single functional material.

Applications of Electroplating Across Industries

The versatility of electroplating has resulted in applications across numerous sectors. One of the most prominent uses is corrosion prevention. Metals like iron and steel are prone to rusting, which compromises structural integrity and longevity. Electroplated coatings of chromium, nickel, or zinc form a protective barrier that prevents oxidation, significantly extending the life of industrial equipment, automotive parts, and infrastructure components.

In electronics and semiconductors, electroplating enables the deposition of conductive layers on circuit boards, connectors, and microchips. Gold and silver coatings enhance electrical conductivity, reduce contact resistance, and prevent tarnishing. The precision of electroplating at microscopic scales also facilitates the creation of nanoscale devices, sensors, and interconnects, where uniformity and thickness control are paramount.

The aesthetic and decorative industry relies on electroplating for jewelry, watches, and household fixtures. By depositing metals like gold, silver, and rhodium, manufacturers achieve visual appeal while maintaining wear resistance. In some cases, electroplating is combined with surface texturing or engraving to produce intricate designs with high durability.

Medical devices also benefit from electroplating. Biocompatible coatings such as titanium or platinum enhance the performance of implants, stents, and surgical tools. Electroplating improves corrosion resistance in physiological environments, reduces friction, and supports sterilization processes, ultimately contributing to patient safety and device longevity.

A table summarizing key industrial applications and benefits illustrates the breadth of electroplating:

| Industry | Purpose of Electroplating | Benefits |

|---|---|---|

| Automotive | Chrome/nickel plating on parts | Corrosion resistance, aesthetic appeal, wear resistance |

| Electronics | Gold/silver plating on connectors | Enhanced conductivity, reduced contact resistance, oxidation protection |

| Jewelry & Decoration | Gold/silver/rhodium plating | Visual appeal, durability, scratch resistance |

| Medical Devices | Titanium/platinum coatings | Biocompatibility, corrosion resistance, reduced friction |

| Industrial Machinery | Nickel/steel plating | Hardness, chemical resistance, lifespan extension |

Advances in Nanocoatings and Surface Engineering

Recent developments in surface chemistry and nanotechnology have expanded the capabilities of electroplating. Nanocoatings — ultra-thin layers with nanometer-scale precision — allow unprecedented control over material properties. By manipulating crystal structures, grain size, and surface roughness at the nanoscale, engineers can enhance hardness, reduce friction, and tailor optical or catalytic properties.

For example, nanostructured nickel or copper coatings demonstrate exceptional wear resistance and adhesion compared to conventional layers. Nanoparticle incorporation during electroplating introduces composite coatings that combine metallic and ceramic properties, resulting in multifunctional surfaces. These advances have implications for aerospace, electronics, energy storage, and renewable energy technologies.

Surface chemistry also informs the development of functional coatings. Hydrophobic or superhydrophobic electroplated layers can repel water, oil, or contaminants, enhancing self-cleaning, anti-fouling, and corrosion-resistant properties. Similarly, catalytic coatings deposited via electroplating support chemical reactions in fuel cells, sensors, and environmental remediation applications. By engineering interactions at the interface between the coating and its environment, surface scientists create materials that actively perform tasks beyond structural or decorative functions.

Challenges and Future Directions

Despite its versatility, electroplating presents several challenges. The use of toxic chemicals such as cyanides, hexavalent chromium, and heavy metals raises environmental and health concerns. Industrial-scale electroplating requires careful waste management, regulatory compliance, and sustainable practices to minimize ecological impact. Researchers are exploring alternative chemistries, including ionic liquids, non-toxic electrolytes, and pulse plating techniques, to address these concerns.

Another challenge is ensuring consistent quality at micro- and nano-scales. Achieving uniform thickness, adhesion, and morphology across complex geometries demands precise control of current, temperature, and electrolyte composition. Advanced monitoring systems, modeling, and machine learning are increasingly applied to optimize electroplating processes and predict defects.

Looking forward, the integration of smart coatings and multifunctional electroplated surfaces promises to revolutionize material science. Coatings that respond to environmental stimuli, conduct electricity selectively, or exhibit self-healing properties are emerging areas of research. These innovations leverage surface chemistry principles to extend beyond protection and aesthetics, creating materials that actively interact with their surroundings for improved performance and longevity.

Conclusion

Electroplating exemplifies the profound interplay between surface chemistry and materials science. By depositing metal layers onto substrates, it enhances durability, functionality, and appearance across countless industries. From corrosion prevention and electronic conductivity to aesthetic appeal and biomedical applications, electroplating demonstrates the transformative power of controlled surface engineering.

Advances in nanocoatings, composite layers, and smart surfaces continue to expand the potential of electroplating. As technology progresses, the field increasingly emphasizes sustainability, precision, and multifunctionality, ensuring that electroplated materials not only meet modern industrial demands but also align with environmental responsibility.

Understanding the principles of surface chemistry remains essential to harnessing the full potential of electroplating. By controlling interactions at the interface, scientists and engineers create materials that are stronger, more durable, and tailored to specific applications. Electroplating is thus more than a manufacturing process — it is a scientific approach that shapes the very surface of materials, unlocking performance and innovation at every scale.